Material :

WCB / WC6 / LCB / CF8 / CF8M / CF3 / CF3M etc

Pressure Rating :

150# / 300# / 600#

Operation :

Hand Wheel / Gear / Actuated (Pneumatic/Electric)

Trims Material :

Available on requirement like

Trim = 1, 2, 5, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18

Tolerance :

Face to face :

± 2.0mm for NPS ≤ 10”& ± 3.0mm for NPS > 10”

| STANDARDS | |

|---|---|

| Design & Mfg. Std. | API 600 / BS 1414 |

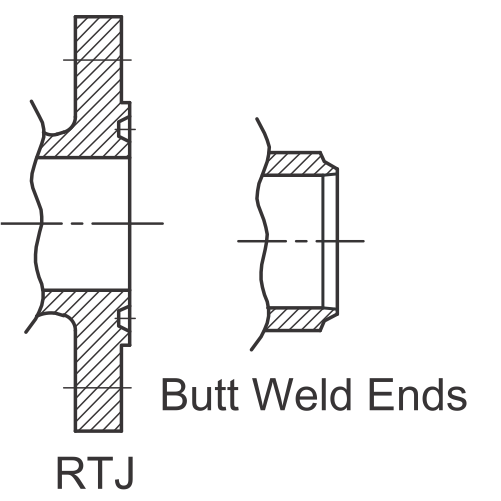

| Face to Face | ASME B16.10 |

| End Connection | Flange Ends – ASME B 16.5 |

| Butt Weld Ends – ASME B 16.25 | |

| Inspection & Testing Standard | API 598 / BS EN 12266-Part-I |

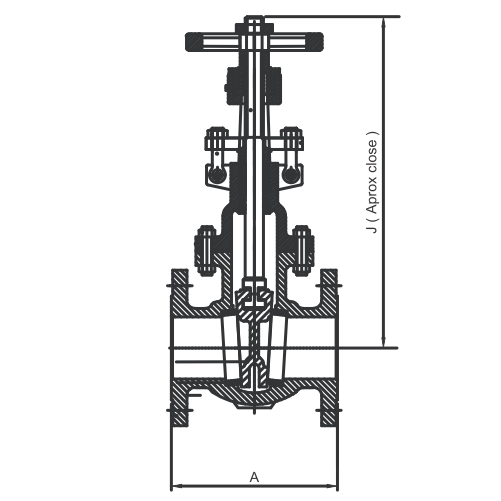

| CLASS 150 | |||||||

|---|---|---|---|---|---|---|---|

| Size | A (MM) | J | Weight (kg) | ||||

| NPS | DN | RF | RTJ | BW | MM | FE | BW |

| 1/2" | 15 | 108 | 108 | 108 | 172 | 5 | 4 |

| 3/4" | 20 | 117 | 117 | 117 | 187 | 5.8 | 5 |

| 1” | 25 | 127 | 140 | 127 | 258 | 7.9 | 7 |

| 1.1/2” | 40 | 165 | 178 | 165 | 278 | 12.8 | 10.5 |

| 2” | 50 | 178 | 191 | 216 | 375 | 22 | 19 |

| 2.1/2” | 65 | 190 | 203 | 241 | 393 | 31 | 24 |

| 3” | 80 | 203 | 216 | 282 | 473 | 35 | 27 |

| 4” | 100 | 229 | 242 | 305 | 570 | 55 | 44 |

| 5” | 125 | 254 | 267 | 381 | 664 | 82 | 70 |

| 6” | 150 | 267 | 280 | 403 | 765 | 97 | 92 |

| 8” | 200 | 292 | 305 | 419 | 995 | 149 | 130 |

| 10” | 250 | 330 | 343 | 457 | 1178 | 255 | 229 |

| 12” | 300 | 356 | 369 | 502 | 1375 | 360 | 345 |

| 14” | 350 | 381 | 394 | 572 | 1525 | 520 | 490 |

| 16” | 400 | 406 | 419 | 610 | 1735 | 630 | 600 |

| 18” | 450 | 432 | 445 | 660 | 1906 | 803 | 775 |

| 20” | 500 | 457 | 470 | 711 | 2095 | 1040 | 1000 |

| 22” | 550 | 482.6 | 495.6 | 762 | 2340 | 1080 | 1050 |

| 24” | 600 | 508 | 521 | 813 | 2525 | 1310 | 1170 |

| CLASS 300 | |||||||

|---|---|---|---|---|---|---|---|

| Size | A (MM) | J | Weight (kg) | ||||

| NPS | DN | RF | RTJ | BW | MM | FE | BW |

| 1/2” | 15 | 140 | 151 | 140 | 172 | 6.5 | 6 |

| 3/4” | 20 | 152 | 165 | 152 | 187 | 7.5 | 7 |

| 1” | 25 | 165 | 178 | 165 | 258 | 11.5 | 10 |

| 1.1/2” | 40 | 190 | 203 | 190 | 278 | 18 | 17 |

| 2” | 50 | 216 | 232 | 216 | 375 | 28 | 20.5 |

| 2.1/2” | 65 | 241 | 257 | 241 | 393 | 52 | 41 |

| 3” | 80 | 282 | 298 | 282 | 473 | 57 | 44 |

| 4” | 100 | 305 | 321 | 305 | 570 | 86 | 63 |

| 5” | 125 | 381 | 397 | 381 | 664 | 127 | 101 |

| 6” | 150 | 403 | 419 | 403 | 765 | 170 | 139 |

| 8” | 200 | 419 | 435 | 419 | 995 | 402 | 375 |

| 10” | 250 | 457 | 473 | 457 | 1178 | 528 | 470 |

| 12” | 300 | 502 | 518 | 502 | 1375 | 670 | 570 |

| 14” | 350 | 762 | 778 | 762 | 1525 | 827 | 710 |

| 16” | 400 | 838 | 854 | 838 | 1735 | 1200 | 1160 |

| 18” | 450 | 914 | 930 | 914 | 1906 | 1410 | 1240 |

| 20” | 500 | 991 | 1010 | 991 | 2095 | 1900 | 1650 |

| 24” | 550 | 1143 | 1165 | 1143 | 2340 | 2678 | 2500 |

| CLASS 600 | |||||||

|---|---|---|---|---|---|---|---|

| Size | A (MM) | J | Weight (kg) | ||||

| NPS | DN | RF | RTJ | BW | MM | FE | BW |

| 1/2” | 15 | 165 | 163 | 165 | 172 | 9.5 | 8.5 |

| 3/4” | 20 | 190 | 190 | 190 | 186 | 10.5 | 9 |

| 1” | 25 | 216 | 216 | 216 | 262 | 16.5 | 15 |

| 11/2” | 40 | 241 | 241 | 241 | 283 | 21 | 19 |

| 2” | 50 | 292 | 295 | 292 | 428 | 40 | 35 |

| 21/2” | 65 | 330 | 333 | 330 | 492 | 63 | 58 |

| 3” | 80 | 356 | 359 | 356 | 534 | 83 | 77 |

| 4” | 100 | 432 | 435 | 432 | 680 | 145 | 135 |

| 5” | 125 | 508 | 511 | 508 | 805 | 220 | 200 |

| 6” | 150 | 559 | 562 | 559 | 918 | 305 | 280 |

| 8” | 200 | 660 | 663 | 660 | 1122 | 510 | 475 |

| 10” | 250 | 787 | 790 | 787 | 1252 | 805 | 760 |

FACE TO FACE DIMENSIONS FOR GATE VALVES

| MATERIAL OF CONSTRUCTION | ||||

|---|---|---|---|---|

| PART NAME | CARBON STEEL | ALLOY STEEL | STAINLESS STEEL | |

| Body | A 216 WCB / WCC | A 352 LCB /LCC | A 217 WC6/WC9/C5/C12 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Bonnet | A 216 WCB / WCC | A 352 LCB /LCC | A 217 WC6/WC9/C5/C12 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Seat Ring | A 216 WCB / WCC+13% Cr. | A 351 C F8 | A 217 WC6/WC9/C5/C12 /A 217 CA 15 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Wedge | A 216 WCB+13% Cr. Facing | A 351 C F8 | A 217 WC6/WC9/C5/C12+13% Cr. | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Stem | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A 276 TP 304/316/304L/316L/321 |

| Gland Flange | A 105 / CS/A216 WCB | A 105 / CS | A 105/CS | A1053/CS3/A351 CF8/CF8M/CF3 |

| Back Seat | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A351 CF8/CF8M/CF3/CF3M/CF8C |

| Gland | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A276 TP 304 / 316 / 304L /316 L /321 |

| Joint Sutd | A 193 B7 | A 320 L7 | A 193 B16 | A 193 B7 / B8 |

| Joint Stud Nuts | A 194 2H | A 194 7 | A194 7 | A 194 2H /8 |

| Gland Stud | A 193 B7 | A 320 L7 | A 193 B16 | A 193 B7 / B8 |

| Gland Stud nuts | A 194 2H | A 194 7 | A194 7 | A 194 2H /8 |

| Gasket | Spiral Wounded SS 316 /316L / 304L / 304 / 321 with Grafoil filler | |||

| Stem Packing | Braided Graphite and Die Formed Graphite ring | |||

| Yoke Sleeve | A439 Gr.D2 | |||

| Hand wheel | Below 2”= Malleable Iorn & Above 2” Ductlie Iron | |||